Through Modern

Innovation

ionized hydrogen Peroxide (ihp®)

Every SteraMist product is powered by Binary Ionization Technology (BIT), a patented dual equipment and solution combination that simulates an all-natural atmospheric process.

Unlike many other hydrogen peroxide disinfectants, the killing agent of ionized Hydrogen Peroxide (iHP) results from the ionization of 7.8% hydrogen peroxide (H2O2), creating reactive oxygen species (ROS) that contain hydroxyl radicals (•OH) – one of the most powerful oxidizing agents in nature. Bacteria, fungal spores, and microorganisms that come in contact with iHP are inactivated after the destruction of their proteins, carbohydrates, and lipids, leading to cellular disruption and the quick decontamination of treated surfaces. SteraMist kills in seconds!

EPA #90150 | Health Canada DIN #02469448 | EN 17272

Inspired By DARPA

As an invention funded by a grant provided by the U.S. Defense Advanced Research Projects Agency (DARPA), ionized Hydrogen Peroxide (iHP) was developed as a direct response to weaponized anthrax attacks.

SteraMist iHP began to establish itself in a more mainstream capacity with registration as a Hospital-Healthcare, general, and multiple-use disinfectant with exceptional efficacy against bacteria, bacterial spores, viruses, mold spores, and countless other microorganisms. With iHP achievable solely through Binary Ionization Technology (BIT), the technology became the very first EPA registered combination of both solution and technology to achieve consistent disinfection with repeatable results.

Binary Ionization Technology (BIT) utilizes a solution of 7.8% hydrogen peroxide as a sole active ingredient, naturally enhanced by a cold plasma arc. As a result, the SteraMist application features superior material compatibility with a quick-acting disinfection and decontamination.

OUR IHP® TECHNOLOGY

Discover the power of cold plasma technology.

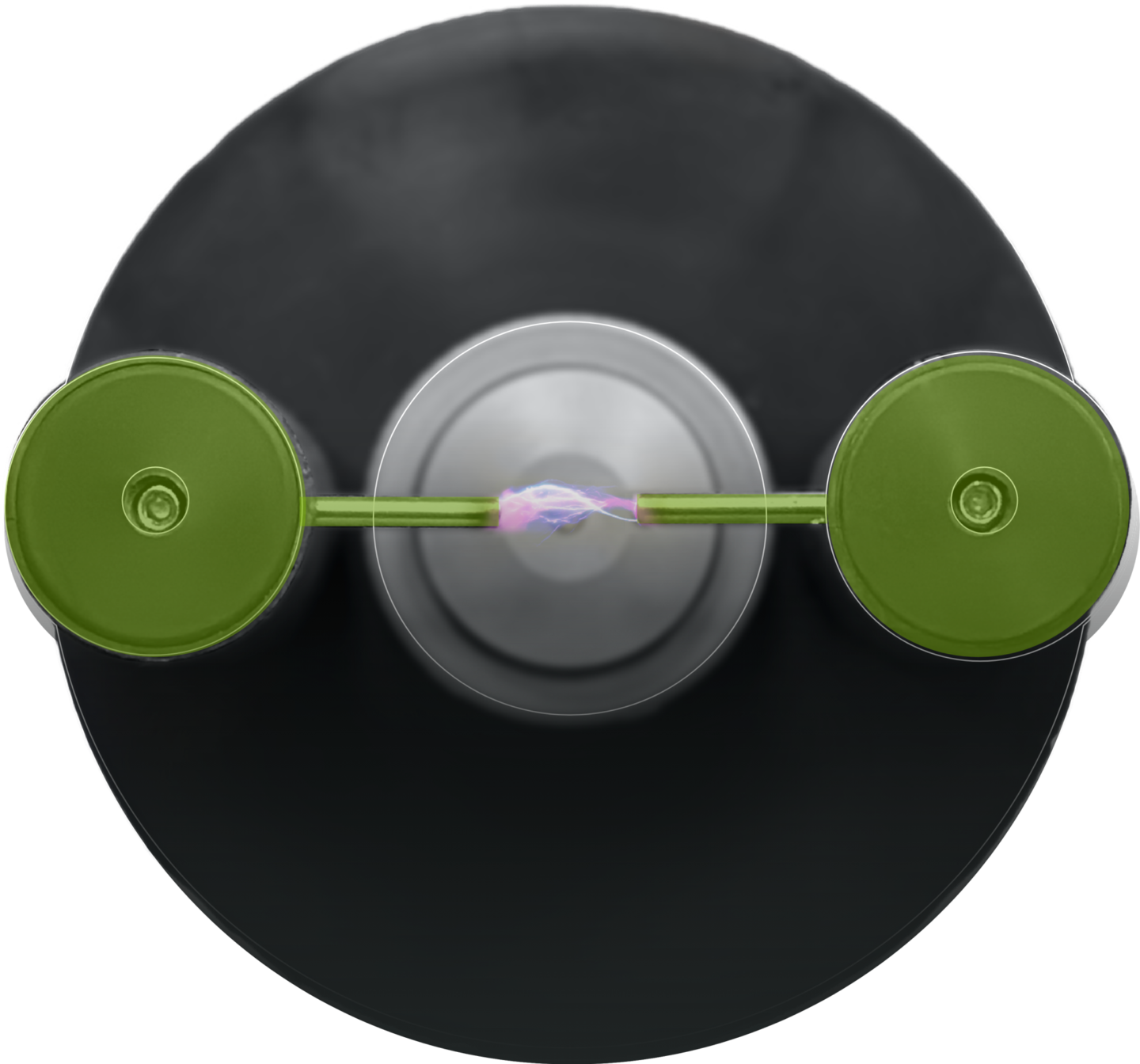

Electrodes

The electrodes are placed at a precise distance to ensure the correct amount of power for the cold plasma arc to produce efficacy.

Nozzle

The nozzle releases the BIT Solution, 7.8% hydrogen peroxide, at a fixed rate and sends it through the cold plasma arc, breaking down the Hydrogen Peroxide to submicron size and turning it to a gas-like state.

Atmospheric Cold Plasma Arc

The cold plasma arc breaks the bonds of hydrogen peroxide to create hydroxyl radicals that provide an instant kill.

Products & Services

View a comprehensive catalog of SteraMist iHP Disinfection and Decontamination Products & Services.

Contact us